Infrastructure facilities solutions

ABEE has state of the art battery cell production, characterization and testing facilities with a dedicated Dry room of 250m² at dew point -60°C. These facilities focus on development of new products, cell design optimization, new processing and manufacturing techniques.

X- Ray Diffraction (XRD) for crystal structure determination, phase analyses and characterisation of battery components during cycling.

Capabilities

- In-situ and In-operando Battery testing (coin cell format)

- Modes: transmission and reflection

- Temperature ranges: -10°C to +600°C

X-ray photoelectron spectroscopy with Auger option (XPS-AES) for elements profiling.

Details

- In-situ and In-operando Battery testing

- Profiling can be across surface or in depth

- 60mm sample holder along with sample transfer shuttle for contamination free testing

- Mu Metal Chamber for improving magnetic shielding

- Temperature ranges: -140°C to 600°C

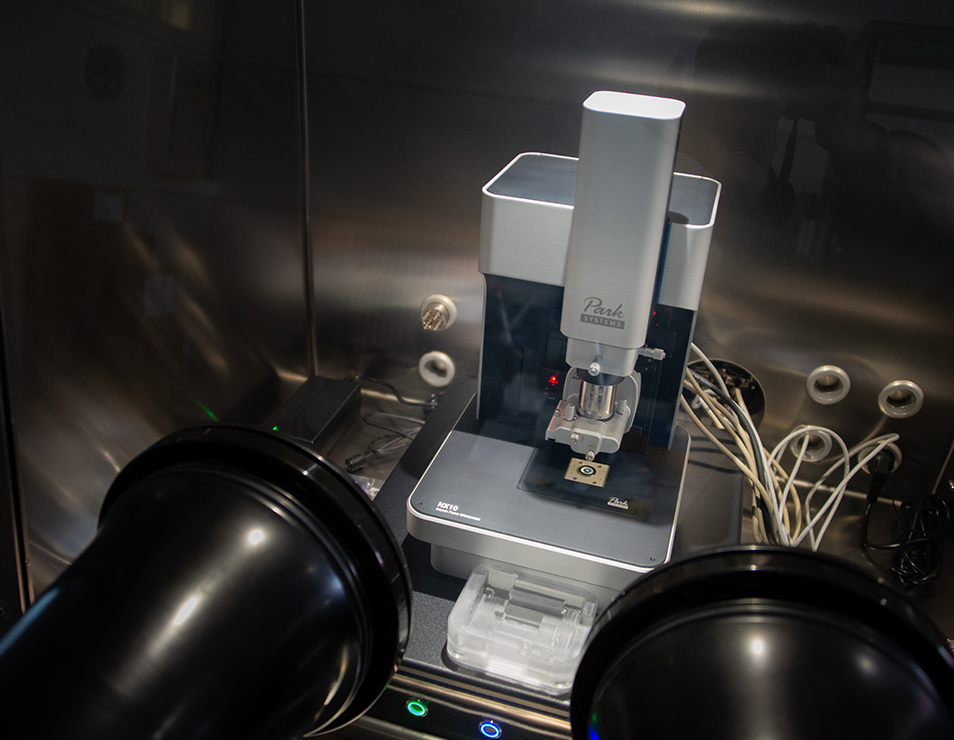

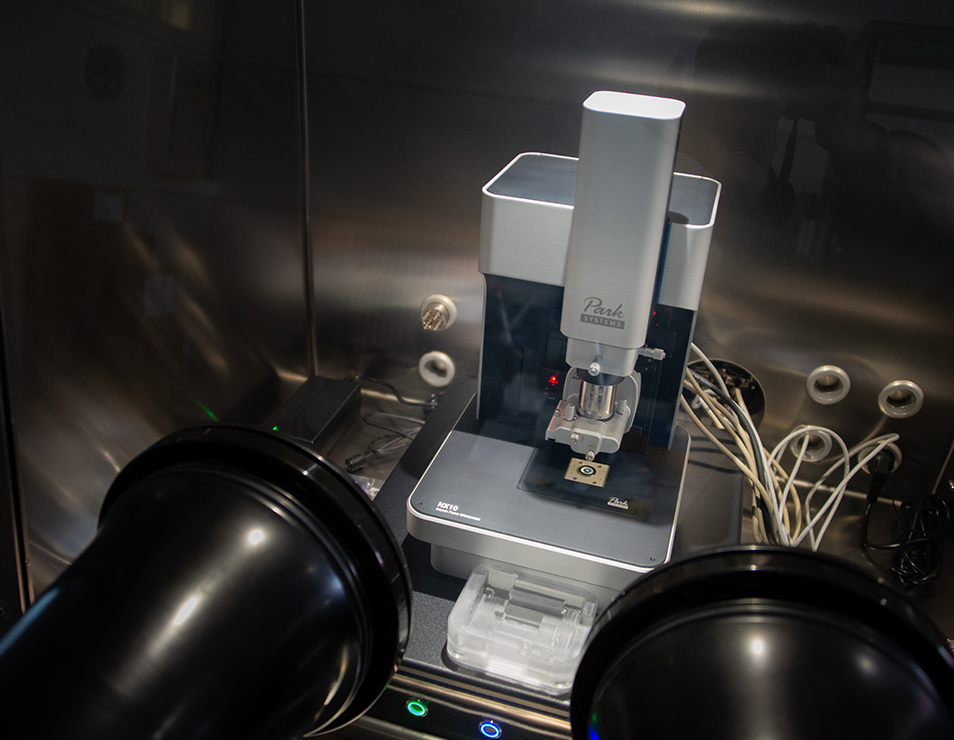

Atomic Force Microscope (AFM) integrated in a glovebox.

Details

- In-situ testing with a faraday cage

- XY scan range: 50 μm × 50 μm

- NCM oscillation frequency: Up to 3 MHz

- Voltage bias range: -10 V to 10 V

- Internal conductive AFM

- Supports standard AFM/SPM modes

Scanning Electron Microscope (SEM) for morphology analysis.

Details

- In-situ testing with solid electrolytes

- Ion milling system for sample preparation

- With EDX option and sample transfer shuttle for contamination free testing

- Spatial distribution of elements by elemental mapping technique

- Ability to scan and map single particle element distribution

Gloveboxes for conventional and next generation Li-ion technologies.

Details

- Dedicated glove boxes for Advanced lithium ion batteries and All solid-state batteries (ASSB) to avoid cross contamination.

- Integrated double glove box makes possible to assemble ASSB cell (up to 200mAh) from slurry preparation to cell fabrication inside the Glove box.

- Vacuum oven also integrated inside the Glove box to evaporate the solvent in the ASSB cell fabrication process.

- Less level of H2O and O2 (less than 0.1ppm) ensures the electrode quality.

- Ability to test (Ex: EIS…) the ASSB cell inside the gloveboxes itself.

Cell testers and climate chambers from coin cells to battery pack level.

Details

- 100 plus channels for coin cell and monolayer pouch cell testing

- 50 plus channels for EIS analysis at various current levels (mA to 100A)

- Thermal chambers availability -20°C climate chambers and (300L to 1500L)

- Cell-module-pack testing: Current ranges at up to 3V voltage range: 50A to 600A

- Number of channels available for a performance testing project: 400 channels

Pilot line for Pouch Cell assembling upto 30 Ah.

Details

- Cell assembly from slurry preparation to electrolyte filling is integrated in a -60°C dewpoint dry room.

- Pilot has been adapted for Gen 3 and Gen 4 Li-ion technologies

Li metal coating line

Details

- Roll-to-roll process (No limitation in the length)

- Li metal can be coated on any substrate for Gen 4 li-ion technology

- In-organic protection layers can also be applied.

Battery Pack Assembly line

Details

- Capability to produce 5000 systems a year

- Customised for any application/chemistry or any requirements

- Can be made cell to pack or cell-module-pack configuration

Other services

ABEE offers a huge panel of services and solutions that you can discover in the page. From infrastucture facilities to battery recycling via design and modeling solutions, feel free to contact us and plan a visit.